New Application Note: First Use of the µFOCUS 450 X-ray Source for Non-Destructive Depth Profiling

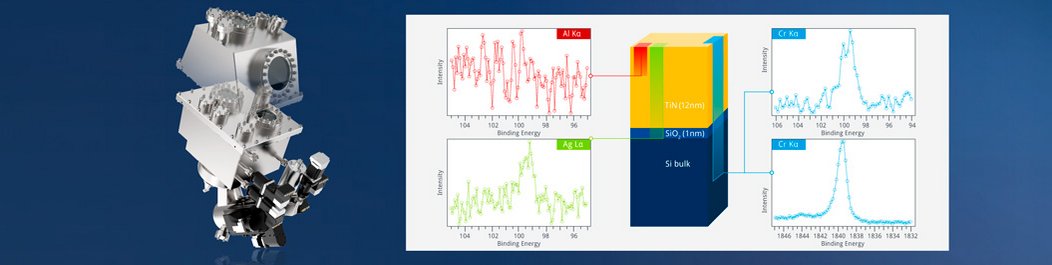

Our latest application note presents the first results achieved with the new µFOCUS 450 X-ray source. With its three different excitation lines, it enables high-resolution, non-destructive depth profiling when combined with Parallel Angle-Resolved X-ray Photoelectron Spectroscopy (PARXPS).

Revolutionary Analysis Technique with VE-PARXPS

The study demonstrates the application of Variable Energy PARXPS (VE-PARXPS) for investigating thin oxide and nitride films. The ability to adjust information depth using different excitation energies significantly enhances analysis capabilities. Combined with the wide-angle AEOLOS 150 analyzer, a comprehensive chemical depth profile was obtained and reconstructed using ITFAP software.

Key Highlights

- Triple Excitation: The µFOCUS 450 enabled measurements using Al Kα (1487 eV), Ag Lα (2984 eV), and Cr Kα (5414 eV).

- Non-Destructive Material Analysis: VE-PARXPS allows for characterization without the need for sputtering.

- Accurate Depth Profiling: The combination of PARXPS and VE-XPS provides detailed insights into material composition and layer thicknesses.

Results & Application Potential

The analysis of titanium nitride (TiN) layers demonstrated that even complex material systems can be precisely examined. For a 12 nm thick TiN layer, the highest excitation energy (Cr Kα) enabled analysis down to the silicon substrate.

With these advancements, our µFOCUS 450 sets new standards in surface analysis. The combination of variable excitation energy and parallel angle-resolved detection opens up new possibilities for materials research and the semiconductor industry.