After a unique SPECS NAP-XPS system has been commissioned in South Korea in 2019, the researchers are now presenting their first outstanding scientific results taken on this instrument in international peer-reviewed journals.

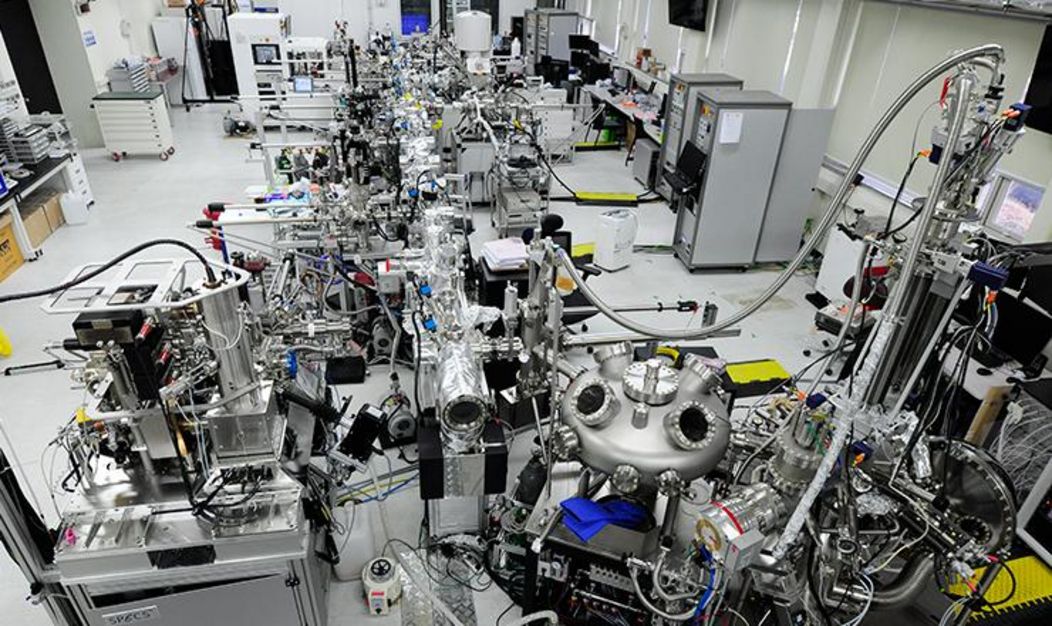

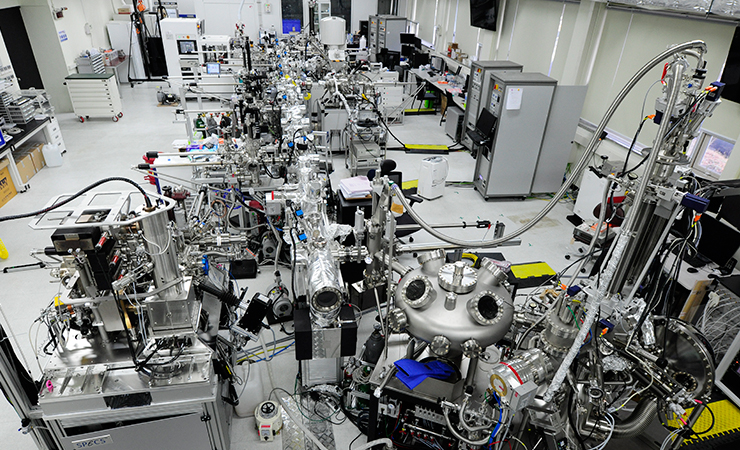

In 2014, SPECS engineers have installed an integrated UHV system connecting the first Korean NAP-XPS with STM, UHV LEEM AC / PEEM analysis modules and various other analytic and deposition subsystem. The backbone of this UHV workbench is a 12 meter long linear UHV transfer system. It is productively working at the Korean Basic Science Institute (KBSI) in Daejeon, South Korea. Based on the great scientific results, especially produced in the NAP-XPS subsystem a second system of similar type has been funded and built by SPECS. Dr. Jouhahn Lee and Dr. Beomgyun Jeong, both leading experts in their fields, were the driving forces behind this project. In 2019, this unique NAP-XPS / NAP-HAXPES system has been installed at the Pohang Light Source (PLS-II) synchrotron facility, and includes some of the most exciting new SPECS technology developed in recent years.

The NAP-XPS/HAXPES endstation, which is managed by Dr. Ki-jeong Kim (Pohang Accelerator Laboratory, PAL) and Dr. Beomgyun Jeong (KBSI), features the following ground breaking technical features:

- a NAP-compatible, monochromated small-spot chromium Cr Kα) x-ray source for offline operation

- a newly developed laser heating mechanism in the sample analysis position, allowing to perform NAP-XPS experiments at pressures up to 30 mbar and 1000 °C sample temperature, including laser guiding optics on the manipulator axis which allows constant heating even while moving the sample

- a windowless, differentially pumped beam entrance connection the end station to the synchrotron beam line

The combination of gas pressures up to 30 mbar, sample temperatures up to 1000 °C and variable photon energies up to the HAXPES range makes the system a one-of-a-kind tool in the world, ideally suited for tasks such as catalytic research and the analysis of buried interfaces.

Managing beamline scientist Dr. Kim has recently published a description of the end station and its capabilities. The paper includes data about beam line characteristics, and XPS intensities as a function of excitation energy and pressure.

Further highlights of the papers published within the past 12 months, utilizing the capabilities of SPECS NAP-XPS systems at KBSI, include the following

Results are published of an experiment where MoS2 is oxidized to MoO3 at temperatures between 100 °C and 350 °C in 1 mbar O2 and 1 mbar Ar, while tracking the work function change of the material in situ in a NAP-XPS experiment. They found a complete oxidation to MoO3 and a related work function increase from 4.66 eV to 5.97 eV at a temperature of 350 °C.

Lee et al., In situ work-function measurement during chemical transformation of MoS2 to MoO3 by ambient-pressure x-ray photoelectron spectroscopy

In situ NAP-XPS experiments have been used to characterize the gas-sensing capability of tin oxide (SnO2) nanorods at room temperature. They were able to synthesize high performance sensors with surprising sensitivity and recovery time. By applying NAP-XPS and other techniques, the researchers were also able to show that the sensing mechanism was driven, unexpectedly, by ionic conduction. Song et. al, Ionic‐Activated Chemiresistive Gas Sensors for Room‐Temperature Operation

The doping of Zirconia (ZrO2) with Cu has been studied to promote catalytic surface activity, and used NAP-XPS to study the interaction of the Zr and Cu cations with various gasses. In a similar study, but using vanadium dopants, the researchers found a more direct influence compared to Cu as a dopant.

Jeon et al., Cu-promoted zirconia catalysts for non-oxidative propane dehydrogenation

Jeon et al., Propane dehydrogenation over vanadium-doped zirconium oxide catalysts

We, SPECS Surface Nano Analysis GmbH in Germany and INA Korea would like to congratulate all researchers for their excellent work and we thank all our customers at Pohang and KBSI for their fruitful collaboration and their trust in our products.