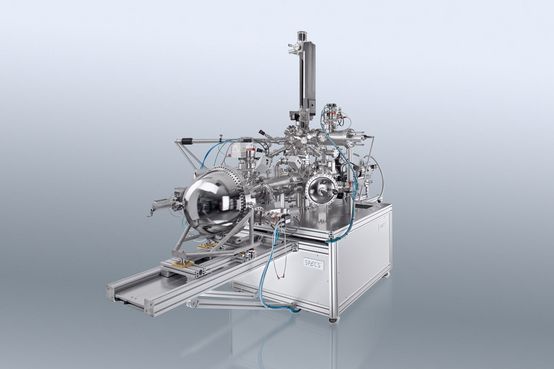

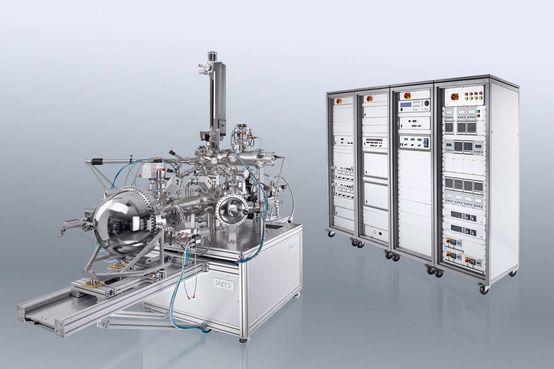

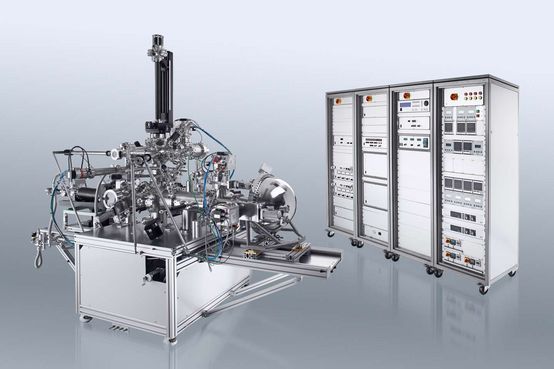

NAP-XPS System Reaction Cell

Near Ambient Pressure XPS System with DeviSim Reaction Cell for Diverse High Pressure Applications

The NAP-XPS system with in-situ reaction cell is designed to keep the sample in a small reaction cell that is placed inside the vacuum chamber hosting the analyzer and the excitation sources. In this way, UHV conditions can be maintained inside the analysis chamber while the in-situ cell is filled up to the required pressure conditions. The possibility to quickly exchange from experiments performed under NAP conditions to experiments in UHV makes this concept very interesting for scientists with very diverse experimental requirements. In addition, the small volume of the in-situ cell compared to the volume of the entire vacuum chamber reduces the interaction of gases with the wall surfaces of the chamber. The DeviSim NAP reaction cell itself can be exchanged very easily in order to avoid cross contamination between different experiments.

This system configuration is very modular and one can start with a basic configuration consisting of an analysis chamber, PHOIBOS 150 NAP analyzer and X-ray monochromator. Later, the system can be upgraded with a fully equipped preparation chamber or can be connected to other different preparation systems like HPC 20, or in-situ EC cell for sample preparation. As well, different analysis systems like NAP-SPM, or IRRAS can be connected to the NAP-XPS system. Depending on the available space, the system can be designed very compact with 2 levels (one for analysis and one sample preparation and transfer) or the preparation chamber can be mounted next to the analysis chamber.

KEY FEATURES

- Powerful and easy to use systems for studies under near ambient pressure conditions

- High performance PHOIBOS 150 NAP electron analyzer

- High flux small spot monochromated X-ray source µ-FOCUS 600

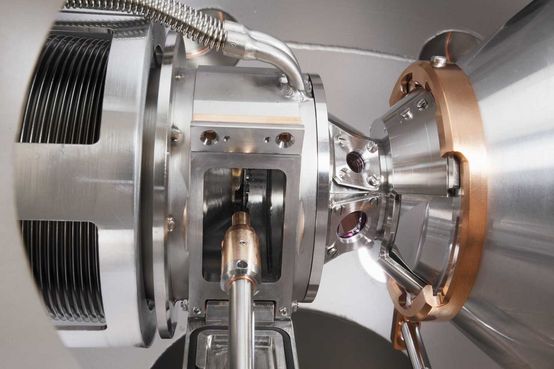

- DeviSim NAP in-situ reaction cell design for perfect control of the sample environment

- Working pressure range from UHV to 50 mbar

- Optional IR laser heating in gaseous environments

- Optional Peltier cooling in gaseous environments

- Customizable gas handling systems

- Efficient upgrade options due to modular system concept

- Well established and proven performance with a large installed base worldwide