Detail

Detail2020 has been a very challenging year for all of us. The pandemic has given us new tasks and we, at SPECS, have tried to accommodate to these tasks as quickly as possible by further increasing our flexibility and adaptability. Especially challenging was the management of our system installations in countries where we were not allowed to travel anymore. Particularly in China we had to handle a large number of components and systems with different degrees of complexity.

Together with our Specs China Support Team we managed to develop a method to complete these installations successfully to the full satisfaction of our customers. We have used remote support as well as time-zone dependent online support to assist our colleagues from SPECS-TII Technology Beijing Co., Ltd. with the installations. The colleagues from the China office have demonstrated a remarkable capability and flexibility that has resulted in the most recent system installations being completed in short installation periods and almost without headquarter support.

We would like to highlight some of the most interesting projects we successfully installed in 2020

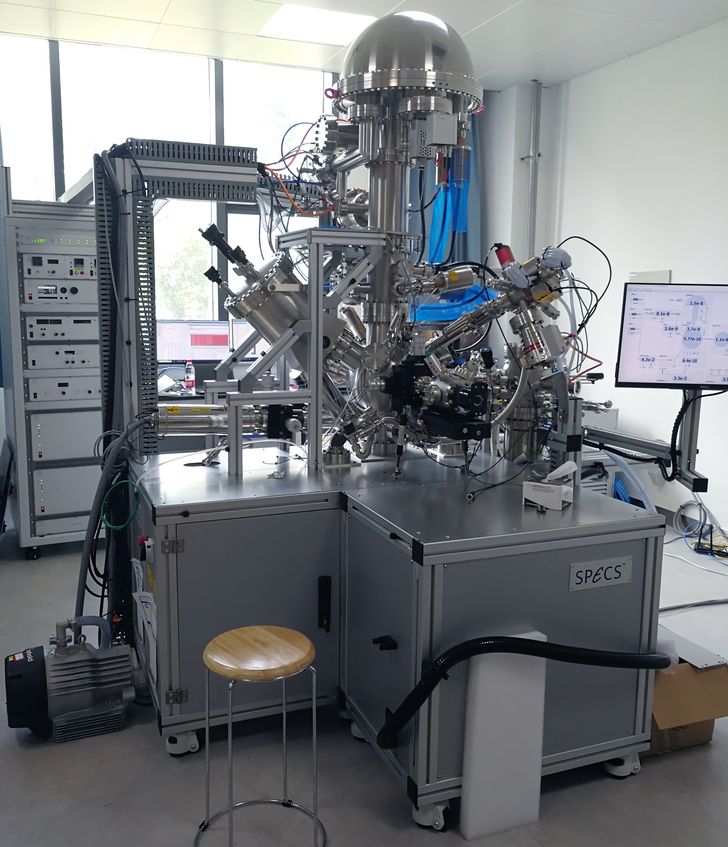

In the group of Prof. Yuriy Dedkov at Shanghai University we have successfully commissioned a complex ARPES system. The system includes as core components a SPECS PHOIBOS 150 2D-CMOS hemispherical analyzer, a high precision 5-axes closed cycle LH manipulator, a high performance UVS 300 UV-source with ETC capillary with a TMM 304 monochromator, and a monochromated X-ray source FOCUS 500. The system also contains a fully equipped preparation chamber with 4-axes manipulator, a high temperature heating station, an Er-LEED 150, as well as an ion source for sample cleaning.

In the group of Prof. Weixin Huang at the University of Science and Technology of China in Hefei, we have successfully installed one of our first ProvenX-NAP systems with backfilling configuration. This system includes a PHOIBOS150 NAP hemispherical analyzer with a 1D-DLD detector, a small spot monochromatic X-ray source µ-FOCUS 600 NAP, as well as a 4-axes sample manipulator equipped with a high performance laser sample heating system that allows for sample heating up to 1000°C under a gas atmosphere of 25 mbar of N2. The system is also equipped with a small spot UV source for NAP applications UVS 300 NAP , an electrochemical cell and a flood gun for charge compensations during XPS measurements under UHV conditions. Additionally, a high pressure cell is connected to the system that allows for sample preparation under gas pressures of up to 20 bars.

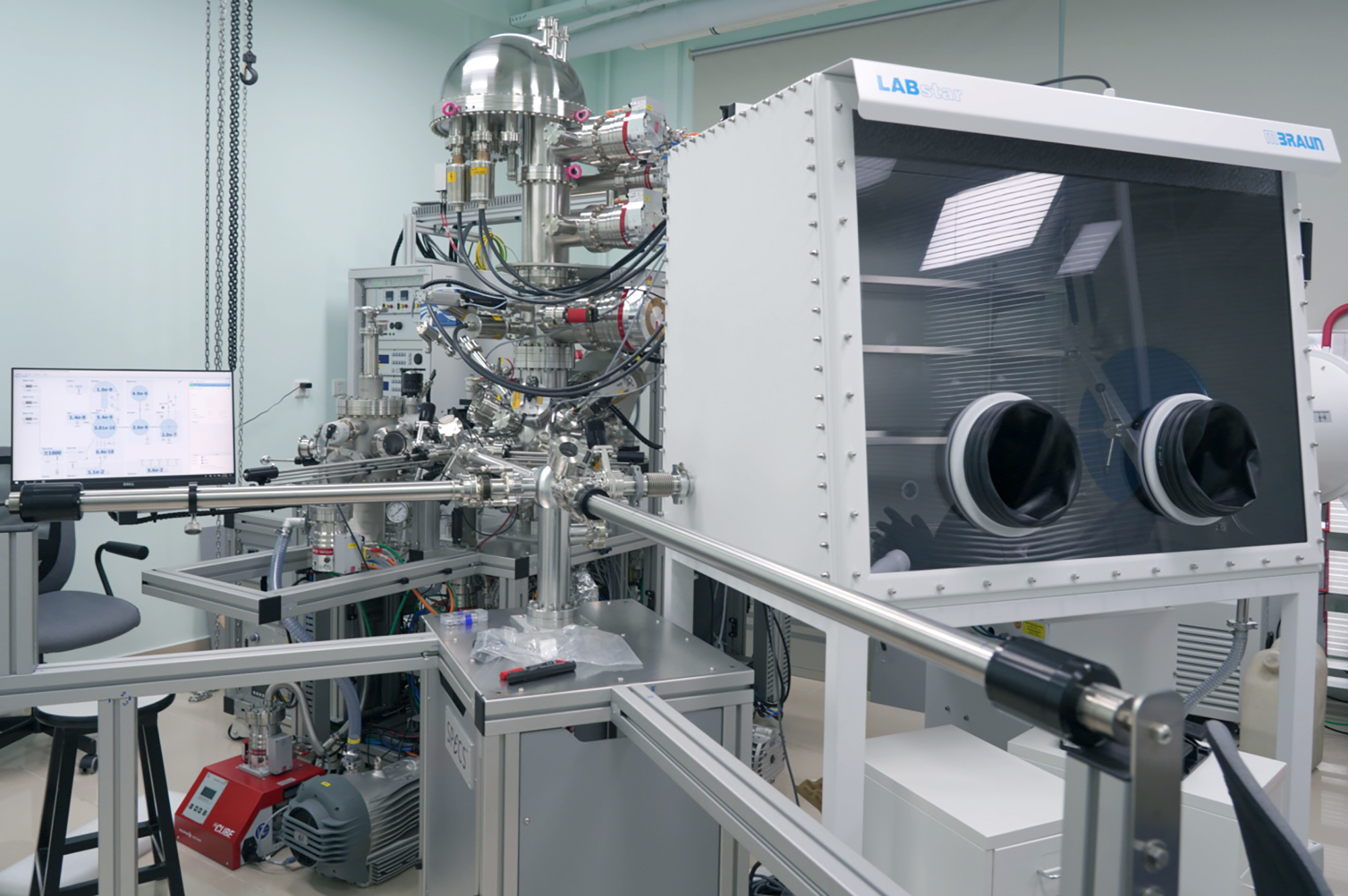

In the group of Prof. Jinglin Xie at Peking University, we have also installed a ProvenX-NAP system in a backfilling configuration. The system also contains a PHOIBOS 150 NAP hemispherical analyzer with a 1D-DLD detector for highest count rates and outstanding linearity, a small spot monochromatic X-ray source µ-FOCUS 600 NAP and a sample manipulator with laser heating. An ion source and a flood gun mounted on the analysis chamber allows for carrying out XPS investigations also under UHV conditions. Additionally, a glove box has been integrated into the system. Thus, different samples can be prepared and introduced into the system without exposure to air by using the glove box or the high pressure cell HPC 20.

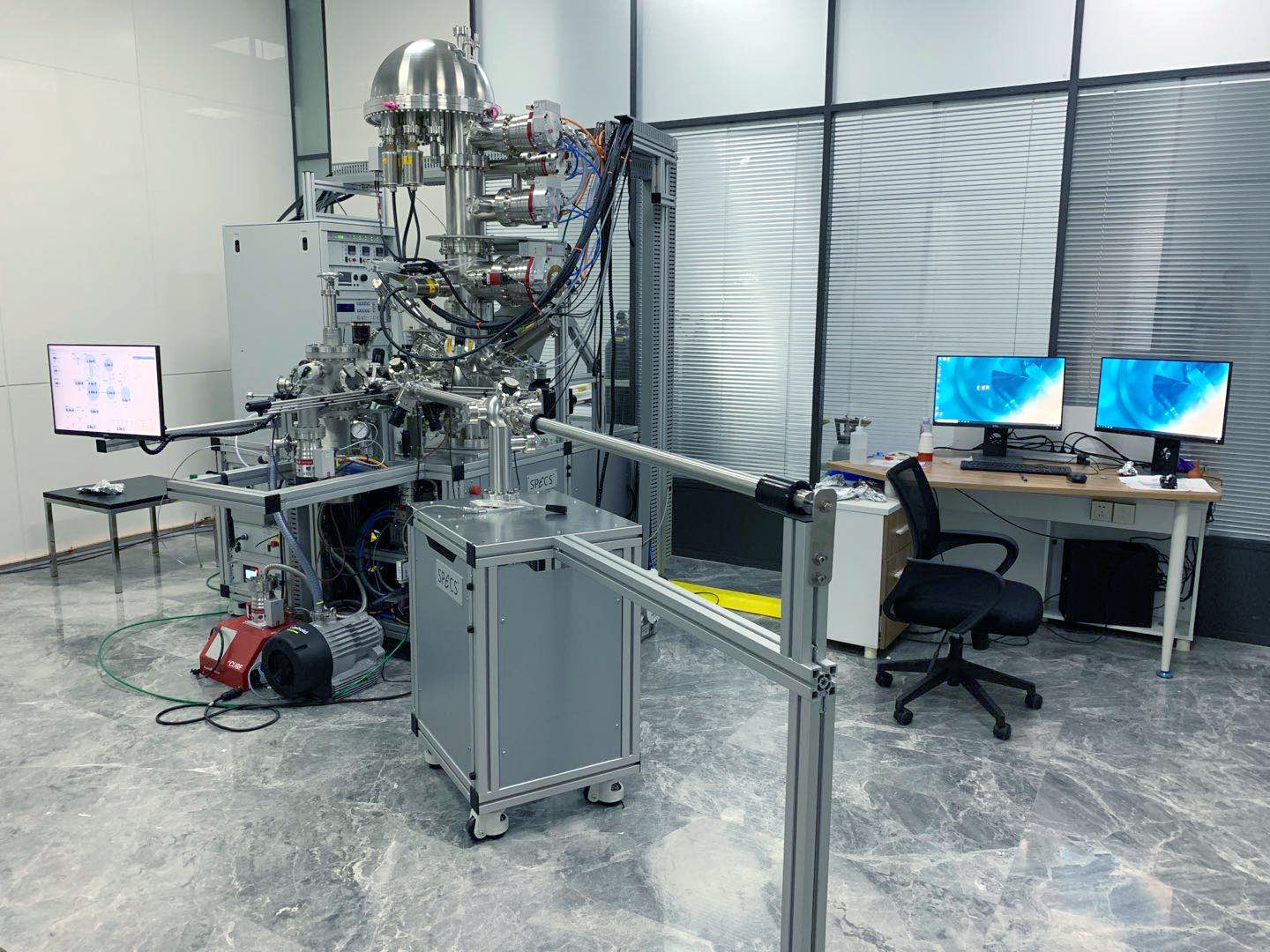

In the group of Dr. Jianjun Chen at Tsinghua University, we commissioned as well a ProvenX-NAP system in a backfilling configuration. The system is equipped with a PHOIBOS 150 NAP hemispherical analyzer with a 1D-DLD detector, a small spot monochromatic X-ray source µ-FOCUS 600 NAP and a sample manipulator with laser heating. A flood gun and an ion source are also mounted onto the analysis chamber. The system is prepared for connection to glove box that together with the high pressure cell HPC 20 gives the outmost flexibility in preparing and analyzing different types of samples.

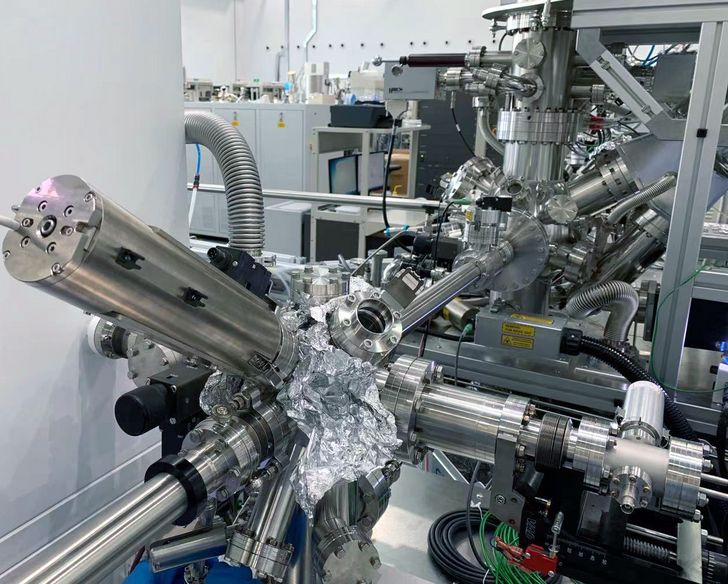

In the group of Dr. Yi Cui at the Suzhou Institute of Nano-Tech and Nano-Bionics (SINANO), we expanded an existing large SPECS multimethod cluster system (NAP-XPS, NAP-SPM, NAP-LEEM) by adding a further preparation module with laser heating and electrochemistry cell. This order is an example of the unsurpassed flexibility and adaptability of SPECS systems.

In the group of Dr. Yue Peng at Tsinghua University in Beijing, we successfully installed and commissioned shortly before Christmas a NAP-SPM system. The system is equipped with an Aarhus 150 NAP-SPM scanning probe microscope that allows for STM and AFM measurements under gas atmospheres up to 100 mbar. In combination with the Nanonis control system and Kolibri sensor , the Aarhus NAP-SPM provides its extreme versatility and flexibility. Thus, operando investigations of catalytic processes on surfaces as well as UHV measurements can be carried out. During the commissioning process we demonstrated atomic resolution under NAP conditions.

We thank the colleagues from the SPECS-TII Technology Beijing Co. for their excellent support and cooperation. We would also like to thank the customers for their confidence and exceptional collaboration. We wish all of them many outstanding results from their new systems.