Detail

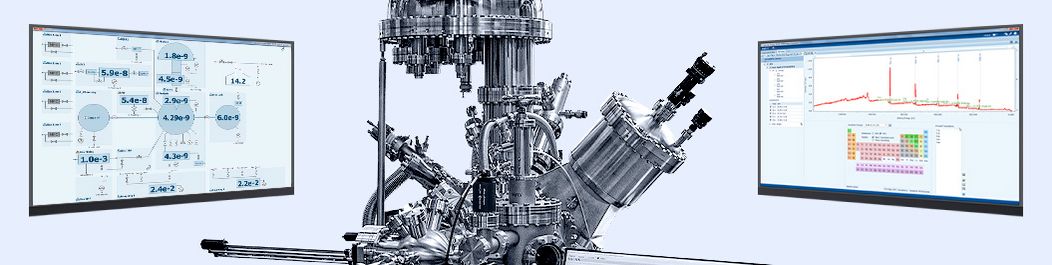

DetailAutomation software suite based on SpecsLab Prodigy

Cutting-edge instruments for scientific research and development are often highly customized solutions of a certain complexity. Accordingly, the handling of such instruments has classically been a challenge for researchers. When correctly used such instruments produce those groundbreaking results that elevate science to a higher level. On the other hand, the skills of the operators are an integral part of the success and sometimes this fact limits reliability and repeatability of the data. To counteract this problem the analytical systems and components from SPECS are equipped with an efficient instrument and process management, that – on demand – releases the researchers from routine tasks and parameter documentation, giving time to concentrate on the real scientific task. This automation includes the automation of the complete vacuum system control, the sample preparation, the process of data acquisition and documentation. Support to use the system also during times of absence of the user remote operation access as well, as scripting, programming and metadata logging tools allow for a maximized uptime and efficiency of the instrument.

The central software for the automation is SpecsLab Prodigy. This is the most powerful data acquisition and data management suite, integrating the control of all necessary components (SPECS and most third-party equipment) with scripts, templates and recipes for data and metadata generation and evaluation. Thus, it enables the user to define and perform smart combinatorial experiments mapping the whole parameter space using a highly personalizable graphical users interface as dashboard. Individual instrument operating system, like the SPECS Keystone for fully automated XPS systems or user defined systems, for instance the proprietary data management systems of the different synchrotron facilities are interfacing as a cockpit to Prodigy.

The module Vacuum Control enables the safe operation of all vacuum related processes, starting from venting, pump down, baking, sample transfer operation to gas inlet and sample surface modification and preparation. As an additional advantage all parameters and status data are permanently recorded, allowing for complete documentation of experiments, but also for forensic identification of causes for “odd“ data.

Fully integrated data evaluation modules, like SPECS ISQAR, complete the software landscape perfectly covering all user tasks using a comprehensive software package from one supplier. With a complete SPECS automation suite for your components or your system your options are beyond imagination. Contact us to discuss your individual solution.