Detail

DetailProvenX Systems: Quintessence of our extensive experience

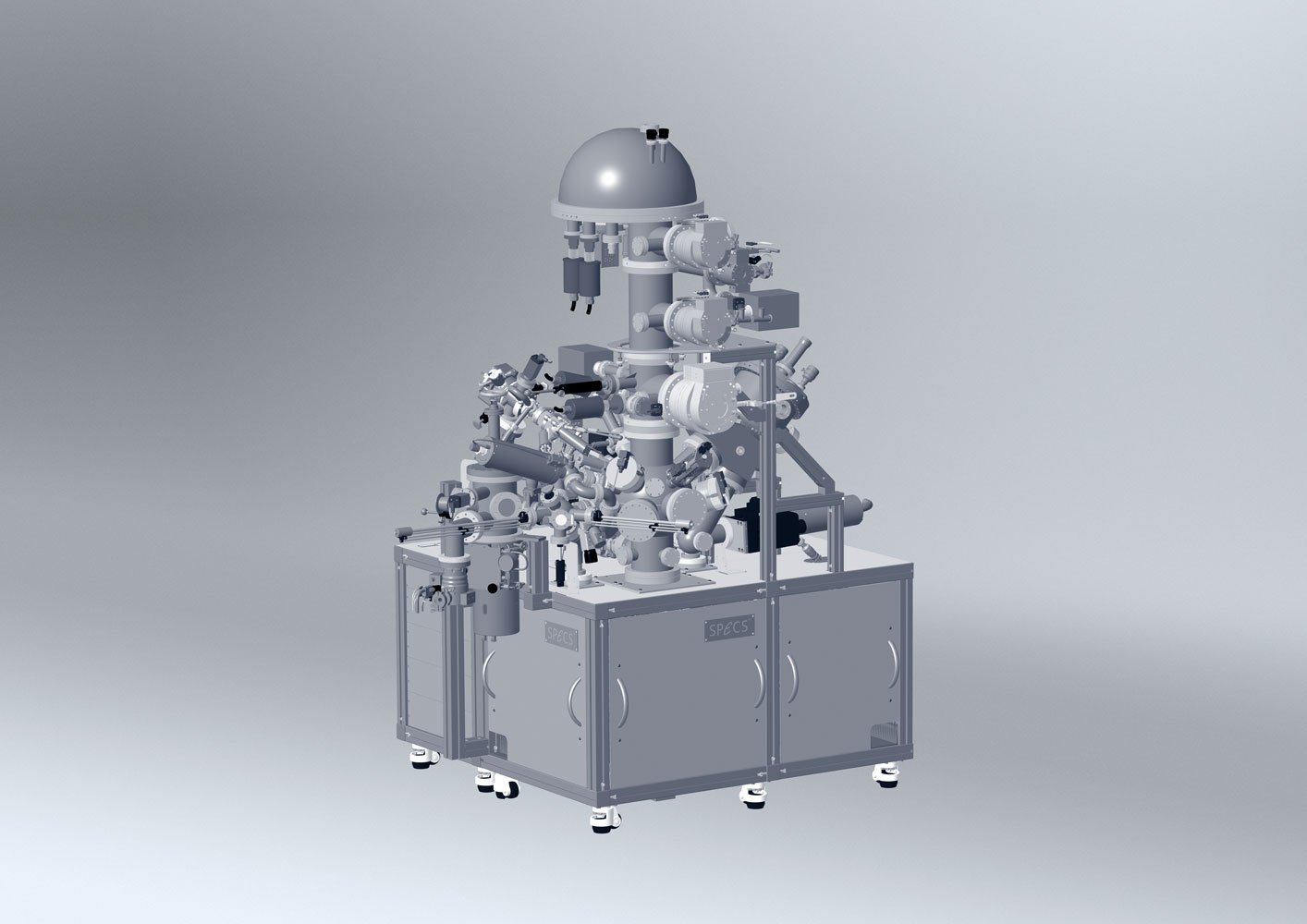

The ProvenX system series represents the quintessence of our extensive knowledge in developing and manufacturing complete surface analysis systems that fulfill the most demanding scientific requirements. The series comprises dedicated systems for ARPES, µ-ARPES and Momentum Microscopy, XPS/UPS as well as NAP-XPS.

The basic principle is to have a standardized, compact system layout with the flexibility of choosing analytical components such as hemispherical electron energy analyzer, X-ray source, UV source, ion source, etc. best suited to research needs. Each configuration has been proven to work since the series uses the same materials, processes, and characteristics of all its predecessors in the field. The system performance data, system specifications, system drawings, installation requirements, and factory and site acceptance test are all readily available, making the ordering process efficient and expediting delivery. The ProvenX system series offers its users convenience without limitation, consistent quality, and verified results in form of a stand-alone system.

In case you are interested in a modular system combining different methods please check our FlexMod Series. In case you need a completely new developed system design please check our customized systems portfolio.

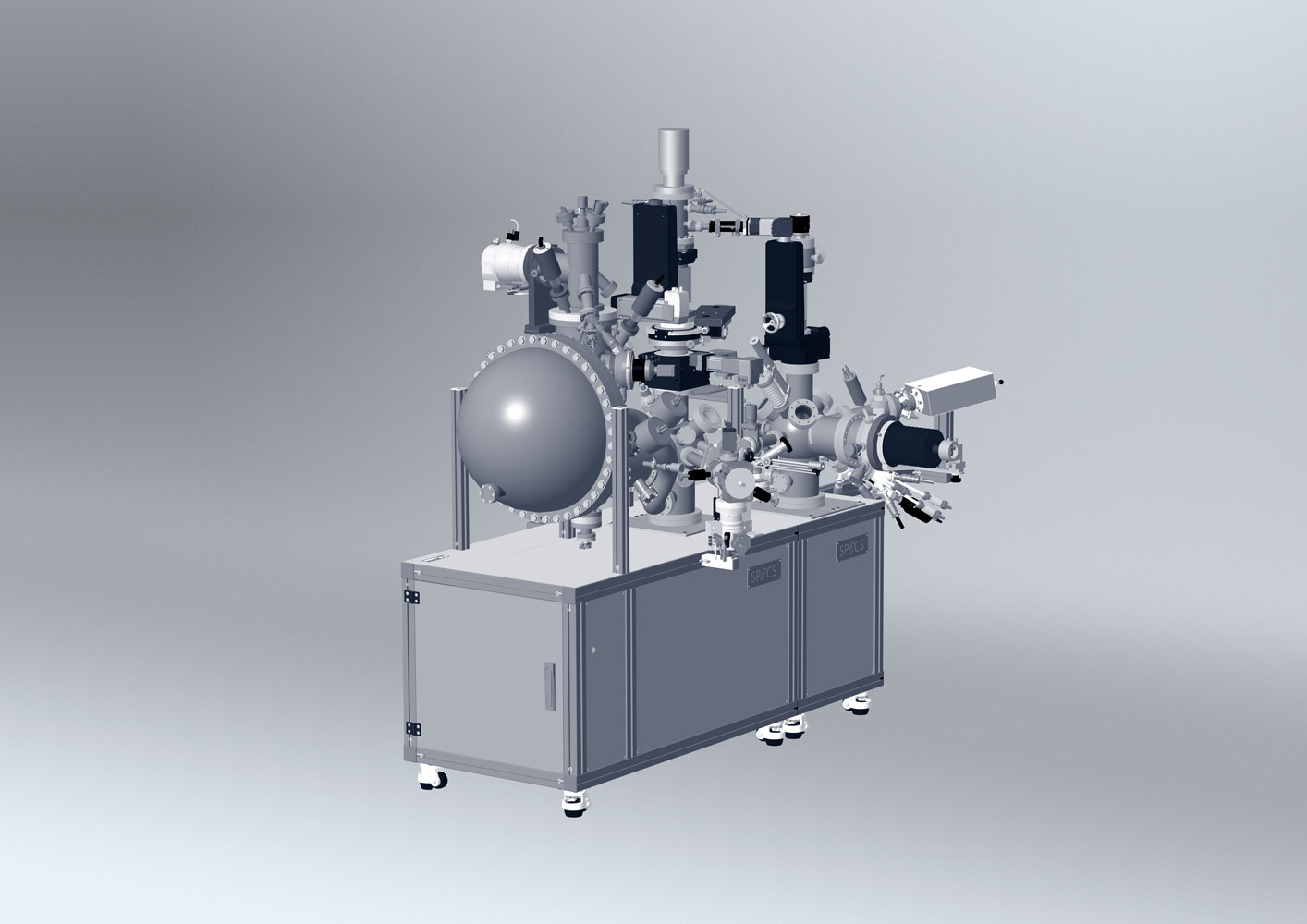

ProvenX-ARPES

The ProvenX-ARPES is a performance-optimized system for state-of-the-art ARPES analysis by high performance XPS analysis on demand. The system features the ASTRAIOS 190 Analyzer with up to +/-±30° acceptance angle, 0.003 Å-1 k-resolution, <1.5 meV energy resolution, high performance UV light sources with µ-focal spot size < 100 µm, low temperature LHe cooled manipulator with 7 K - 400 K or 15 K - 1100 K sample temperature, and an optional monochromatic small spot x-ray source with spot size < 200 µm. Charge compensation is achieved by adding an optional flood gun and the analysis chamber can accommodate an additional electron source for Auger Electron Spectroscopy (AES) as well. The system is connected to a SPECS preparation module for LEED/AES, sputtering, annealing and deposition.

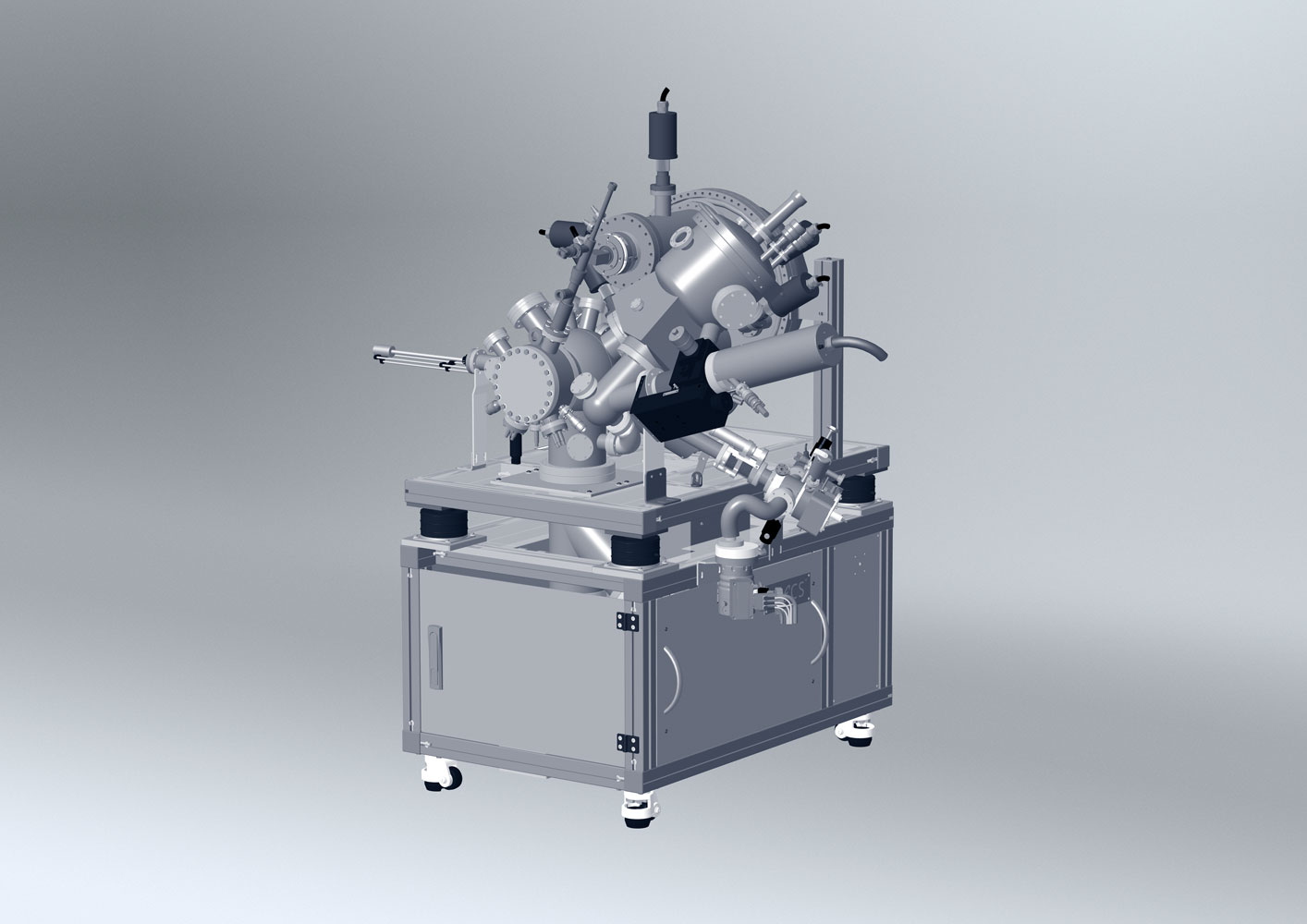

ProvenX-MM

The ProvenX-MM is a dedicated system for state-of-the-art small spot ARPES and Momentum Microscopy analysis completed by high performance XPS analysis on demand. The System features the KREIOS 150 Analyzer with up to ±3,6 Å-1 field of view in reciprocal space, 0.008 Å-1 k-resolution, down to 5 meV energy resolution and down to 100 nm spatial resolution, high performance UV light sources with µ-focal spot size < 100 µm, low temperature LHe cooled sample stage with 9 K - 400 K sample temperature and an optional monochromatic small spot x-ray source with spot size < 200 µm. An upgrade to KREIOS 150 MM with up to ±3,6 Å-1 field of view in reciprocal space, down to <30 meV energy resolution and down to <50 nm spatial resolution is available for demanding momentum microscopy applications. The system can accommodate a SPECS preparation module for LEED/AES, sputtering, annealing and deposition.

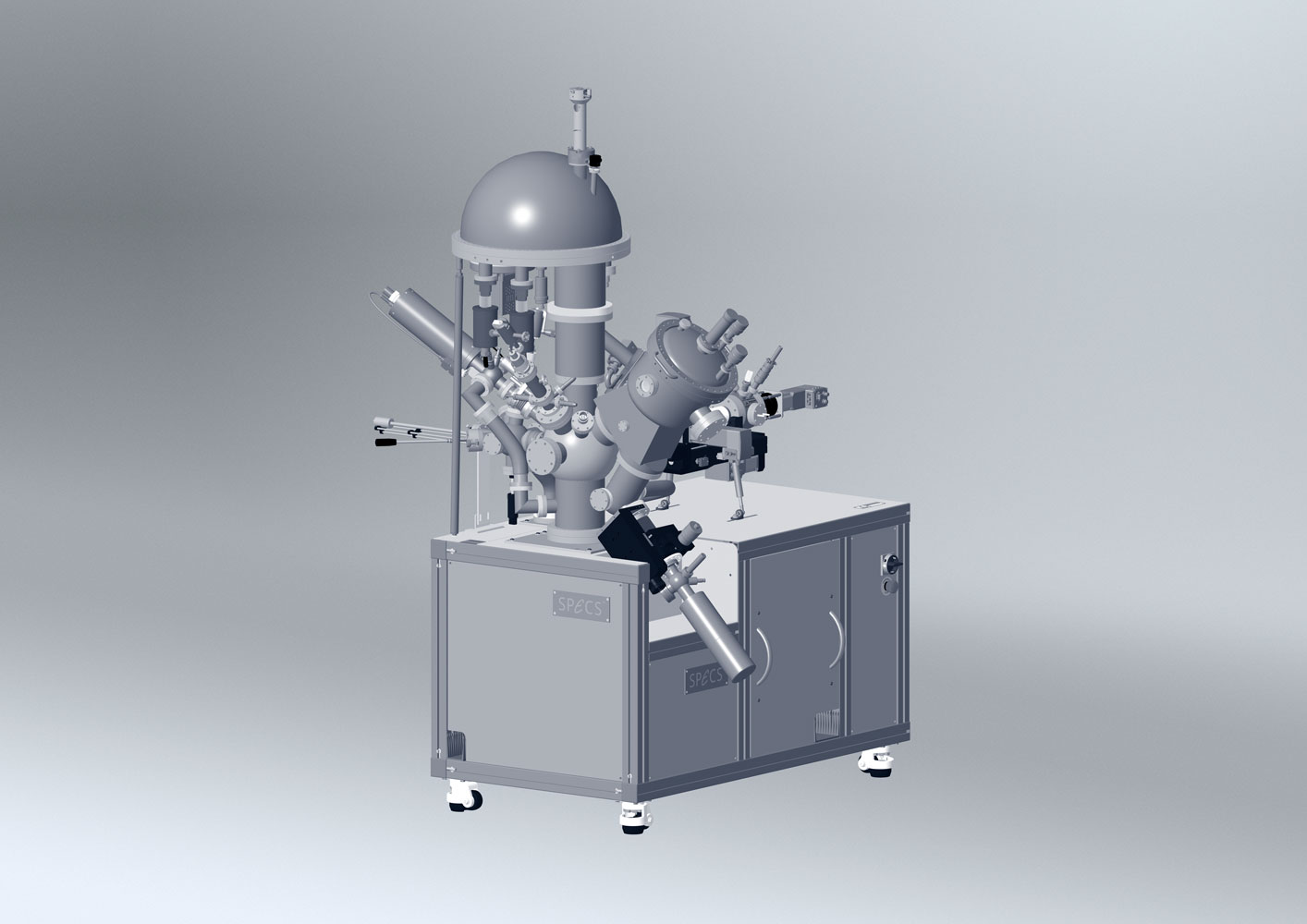

ProvenX-PS

The ProvenX-PS is a performance optimized system for ultimate performance stand-alone XPS and UPS surface analysis. The system features a PHOIBOS electron energy analyzer with up to +/-15° acceptance angle high transmission guns, a versatile monochromatic dual anode X-ray source with Al Kα and Ag Lα anode, and a UV light source on request. A high-performance small spot monochromatic single anode X-ray source with Al Kα anode and spot size < 200 µm can be substituted instead of the dual anode monochromatic X-ray source. Charge compensation can be achieved by an optional flood gun and sputter depth profiling measurements can be carried out by using a small spot ion source or a gas cluster ion beam source. Special samples can be prepared inside a high pressure cell (HPC 20) in a gas atmosphere of up to 20 bar and up to 800 °C temperatures. A SPECS preparation module for LEED/AES, sputtering, annealing and deposition or other system extension can be added to the system.

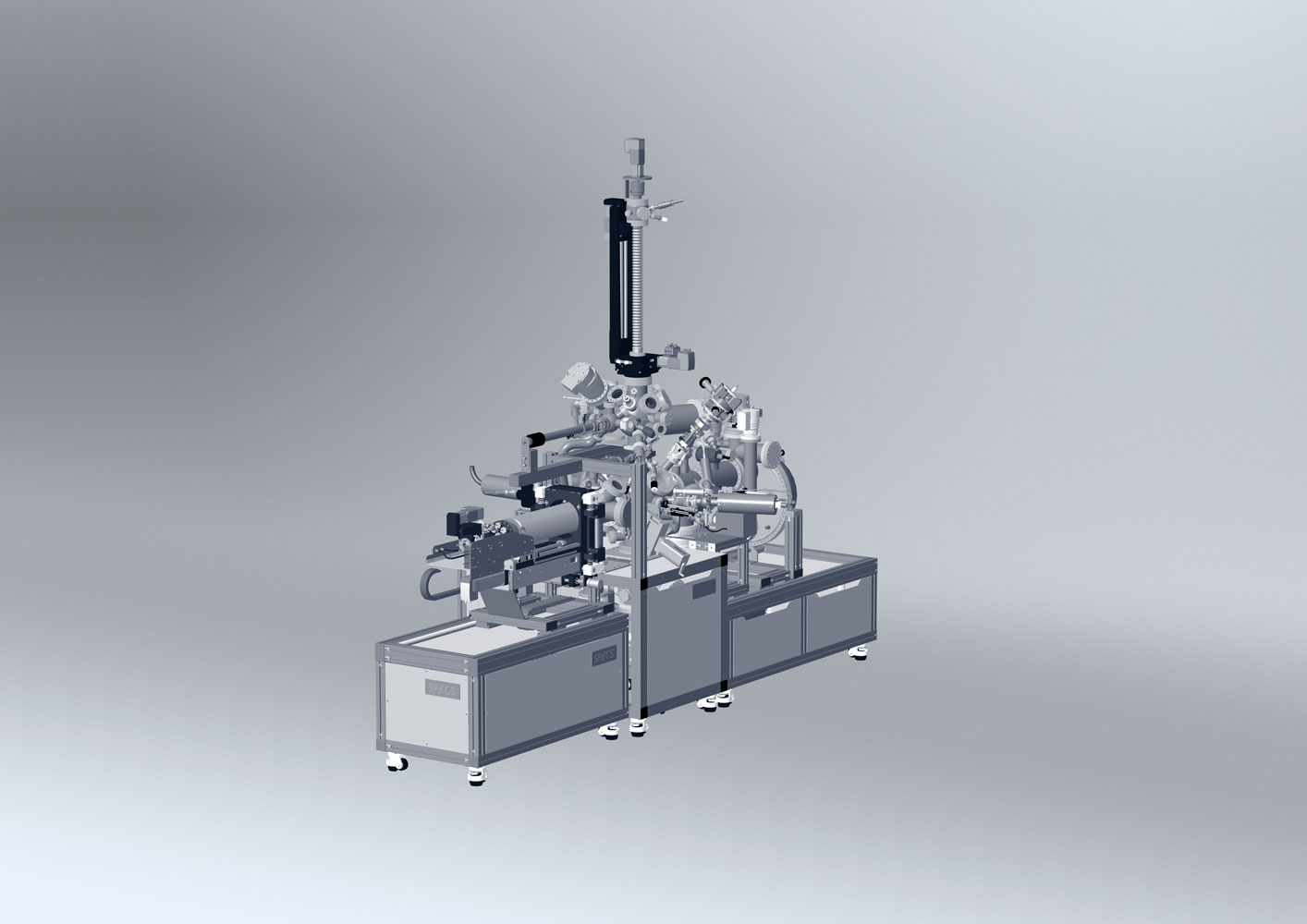

ProvenX-DeviSim NAP

The ProvenX-DeviSim NAP is unique for NAP-XPS/UPS with DeviSim In-Situ Cell Configuration in an optimized system for state of the art measurements from UHV to up to more than 30 mbar pressure range for laboratory use. It contains a PHOIBOS 150 NAP analyzer with unsurpassed transmission and angular acceptance (+/-22° acceptance angle), the cutting edge DeviSim in-situ cell (with e-beam heating, laser heating or Peltier cooling) as a small reactor inserted inside the analysis chamber, a high performance small spot monochromatic X-Ray source µ-FOCUS 600 with Al Kα, anode and spot size < 200 µm, as well as an optional non-monochromatic UV source UVS 300. The system is designed to allow UHV measurements on a designated 4-axes sample manipulator with e-beam heating and LN2 cooling. Additionally, a flood gun can be mounted for charge compensation in pure UHV-XPS experiments and an optional ion source can be used for sputter depth profiling measurements. The sample preparation can be carried out inside a SPECS preparation module mounted on top of the analysis chamber for LEED/AES, sputtering, annealing and deposition.

ProvenX-NAP

The ProvenX-NAP in backfilling configuration is a dedicated system for state of the art NAP-XPS as well as NAP-UPS measurements from UHV up to 30 mbar pressure range. It contains a PHOIBOS 150 NAP analyzer with unsurpassed transmission and angular acceptance (+/-22° acceptance angle), a high performance small spot monochromatic X-Ray source µ-FOCUS 600 NAP with Al Kα anode and spot size < 200 µm, a 4-axes manipulator with NAP compatible heating and cooling capability (laser heating, radiative heating and Peltier cooling) as well as an optional non-monochromatic UV source UVS 300 NAP. For UHV experiments, charge compensation can be achieved by an optional flood gun. Sputter depth profiling measurements in UHV can be performed as well by using an ion source or a gas cluster ion beam. The sample preparation can be carried out inside a special high pressure cell (HPC 20) in gas atmospheres up to 20 bar and 800 °C. The system has the possibility of connecting a manipulator with in-situ refillable flow EC-cell, a preparation module or other system extension.