Detail

DetailRHEED

Interaction of electrons with solid surfaces

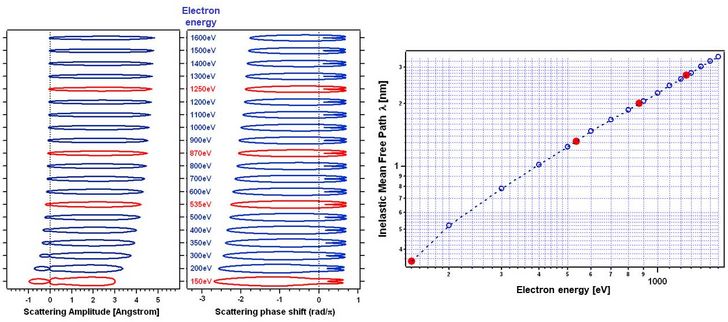

Electrons impinging on a sample surface potentially undergo different processes of interaction. The electron can be absorbed, inelastically scattered under excitation of an electron of a single atom, leading to Auger-electrons or self-ionization, or under excitation of the collective electron gas (plasmon excitation), or under excitation of phonons. Finally the scattering can also be elastical with subsequent superposition of the different electron waves, better known as electron diffraction. Which of the processes is dominant depends on the sample surface, the incident angle and the kinetic energy of the impinging electron. In case of elastic scattering this energy dependence is shown in the set of polar plots of the scattering amplitude and scattering phase shifts for different electron energies between 150 eV and 1500 eV. Obviously backscattering is strong at low energies (like in LEED) and forward scattering is strong at high energies (like in RHEED). This, and the fact, that the penetration depths is increasing with increasing energies, it has consequences for the geometry of the experiments discussed in the following paragraphs.

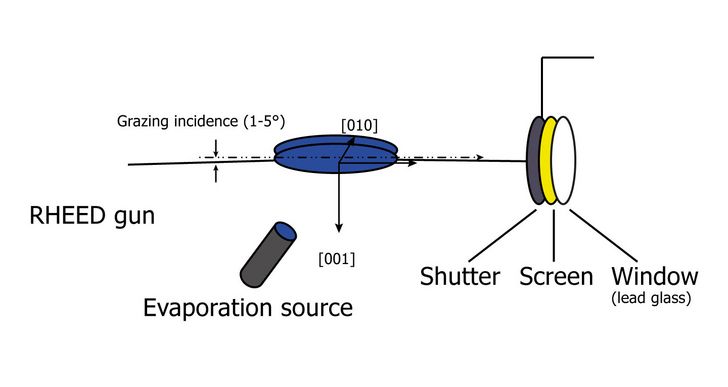

RHEED: Reflection High Energy Electron Diffraction

In Reflection High Energy Electron Deflection the electrons of a kinetic energies between 10 keV and 50 keV are emitted from an electron source and guided onto the sample surface under grazing angles between 1° and 5°. This is at the same time to avoid to large penetration depths into the sample, so to keep the information surface sensitive, and to take benefit from the large forward scattering cross section. The scattered electron are also leaving the sample under grazing angles and are detected on a fluorescent screen. This geometry obviously keeps the sample surface accessible for deposition during the analysis. Thus, RHEED has developed into the perfect method for online monitoring of structural changes during growth and film thickness monitoring and process control. NAP-RHEED setups are available, that allow to work under several mbatr pressure, so that RHEED is not limited to vacuum based deposition methods, like MBE and PVD, but also available for PLD and to certain extends even to CVD or ALD.