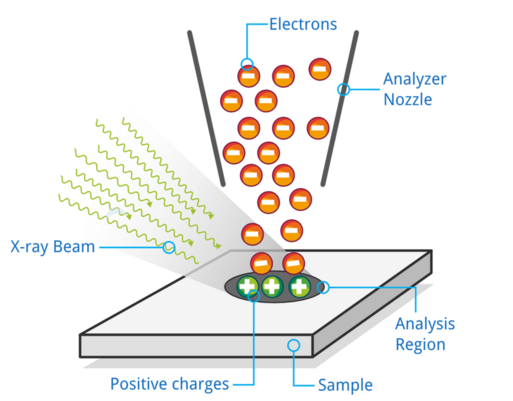

XPS spectra are obtained by illuminating the sample surface with monochromatic X-rays and measuring the energy of the photo-emitted electrons with an information depth of up to 10 nm for standard soft X-ray excitation sources. Thus, it provides qualitative and quantitative information about the elemental composition and the chemical state of the surface.

Classical XPS analysis technique

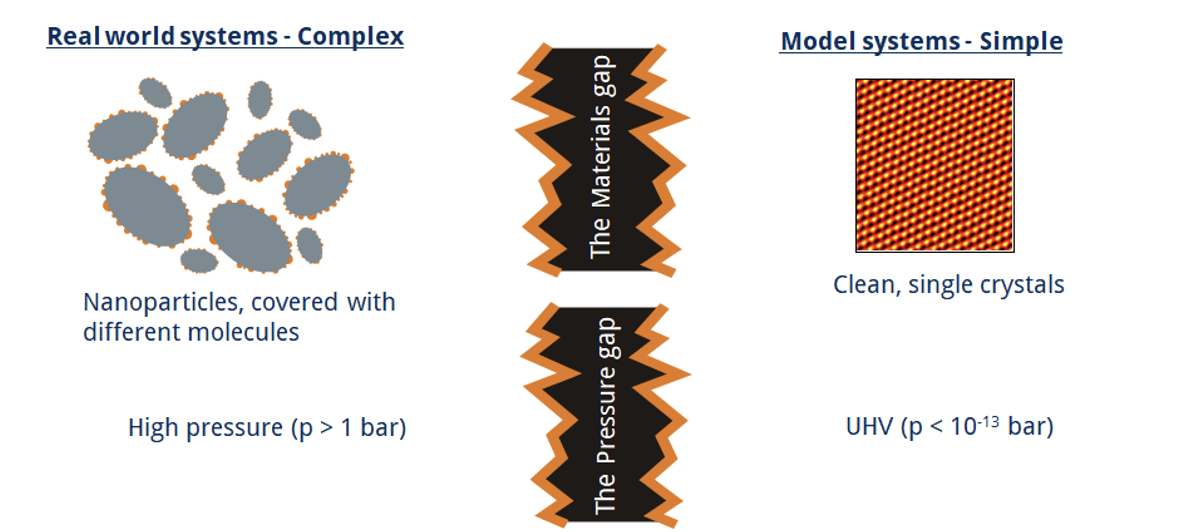

The classical XPS analysis technique is used under UHV conditions and this strongly restricts the type of samples that can be investigated mainly to solid samples or liquids with a very low vapor pressure. Therefore, model systems rather than real samples in their generic environments can be investigated by using standard XPS techniques in UHV.

Thus, in Near-Ambient-Pressure X-ray Photoelectron Spectroscopy (NAP-XPS) the sample is surrounded by a gas atmosphere and no ultra-high vacuum (UHV) conditions are required in the analysis area. Therefore, investigations of a large variety of different samples, including insulating samples, biological samples, gases, liquids and their interfaces are easily accessible. When measuring XPS in a gas atmosphere, the emitted photo-electrons from samples are scattered by collisions with surrounding gas molecules before entering the hemispherical electron analyzer.

Requirements for NAP-XPS measurements

In order to be able to perform XPS measurements at elevated pressures, different requirements have to be fulfilled:

- The electrons have to be “caught” before most of them are inelastically scattered by collisions with gas molecules. Thus, short electron and X-ray travel lengths as well as large angular acceptance of the analyzer are required.

- The pressure gap has to be crossed, which implies the development of analytical components (hemispherical electron analyzer, small spot X-ray and UV-sources) that can work in pressure ranges from UHV to tens of mbar regime or even higher.

- The exact composition, temperature and pressure of the sample environment have to be controlled.

- High signal intensity and fast data acquisition is required, since the chemical processes at surfaces are taking place on a fast time scale.

Many fundamental processes that occur at solid-gases or solid-liquids interfaces play a key role in different application fields like heterogeneous catalysis, energy generation and storage, or environmental science. By using NAP-XPS, in-situ and operando studies under realistic working conditions are possible.

Strengths of NAP-XPS

- Chemical state measurements on surfaces

- Sensitive to all elements except for H and He

- Huge variety of addressable sample systems including insulating samples, powders, liquids, gases, biological molecules

- Investigation at elevated pressures under well controlled conditions (temperature, pressure, type of gas/liquid)

- Operando studies of real devices

Key Applications

- Operando studies of electrochemical energy conversion and storage devices

- In-situ investigations of medical and biological materials

- Processes at interfaces under reactive conditions for e.g. corrosion and catalytic studies

- Surface studies in contact with gaseous or liquid environments

A NAP-XPS system mainly consists of three building blocks, the analysis chamber that accommodates the sample under controlled pressure and temperature conditions, a special electron analyzer with a dedicated differential pumping scheme that collects as many photoelectrons as possible at a distance that is shorter than their mean free path and a high flux small spot X-ray source, with spot sizes smaller than the entrance nozzle of the electron analyzer (usually < 300 µm). There are different system layouts for NAP-XPS systems which mainly differ in the way the sample environment is realized. All designs have specific advantages for specific experimental tasks or conditions.

Additional to NAP-XPS, small spot UV-sources have been developed that are able to work under different gas atmospheres by using a Al-window and differential pumping. With this, NAP-UPS investigations (classically with He I and He II radiation) can be carried out in order to investigate changes in the valence band structure in gas pressures of up to 1 mbar.

NAP-XPS / NAP-UPS techniques are experimentally available for laboratories as well as synchrotrons. In the case of synchrotrons, a special beam entrance stage either with differential pumping or a Si3N4-window can be used as connection of the NAP-XPS system to beamline.

Environmental Charge Compensation

In conventional XPS systems where the analysis region needs to be kept under UHV an effect occurs that is named surface charging. A nonconductive sample that has its electrons continuously removed from the analysis region by the impinging X-ray photons will slowly be charged up positively. The escaping electrons will be influenced in their path and energy by the positive charges at the surface. To prevent the surface from charging up, conventional XPS systems are equipped with charge compensation system (electron and ion sources) that can be tuned in a way that additional charges will be brought to the surface region compensating the lost charges due to the photoionization process. This is a really difficult and time consuming task.

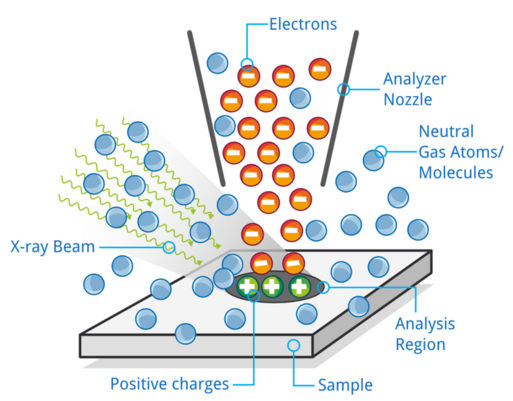

NAP-XPS systems or EnviroESCA are not conventional UHV-XPS systems but Ambient Pressure XPS (AP-XPS) systems, which means that the sample is kept under vapor or gas pressures up to 50 mbar. This implies that there are neutral gas atoms and molecules surrounding the sample, whereas it is not important if the gas atoms or molecules evaporate from the sample surface or if they are introduced inside the analysis chamber by using a built-in gas delivery system.

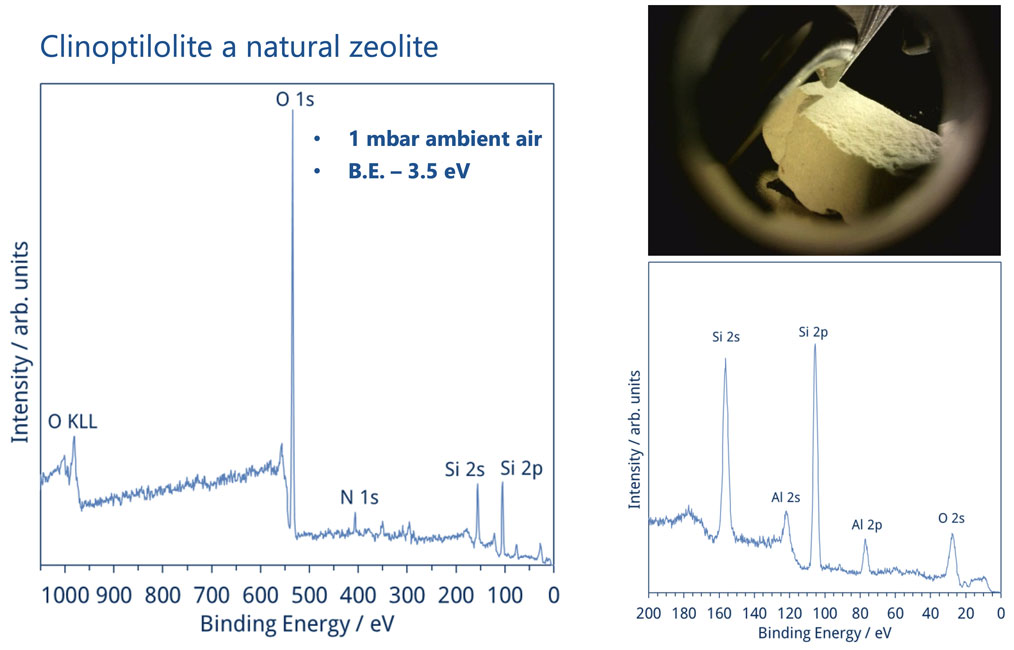

The impinging X-ray photons will also interact with the neutral gas atoms and ionize them, hence generating free positive charged ions and electrons. These free charges act as a charge cloud above the surface layer of the sample, allowing every escaping electron from the surface to be exchanged against an electron of the charge cloud. We call this intrinsic charge neutralization effect Environmental Charge Compensation.

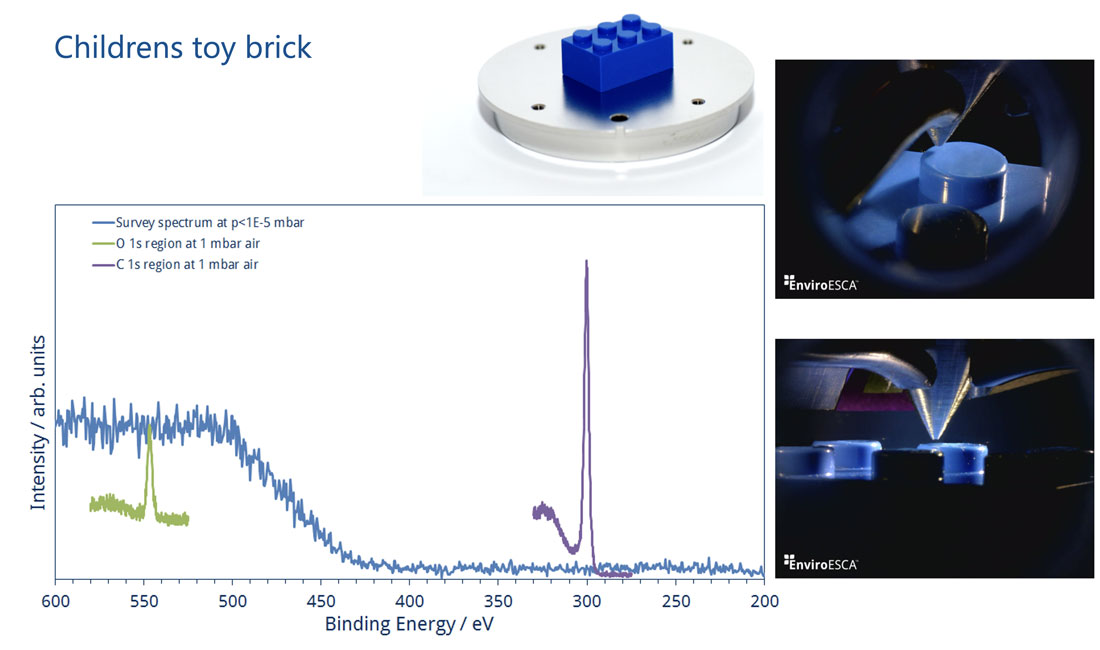

The Environmental Charge Compensation Effect is an intrinsic effect that takes place in any NAP-XPS system with sufficiently broad X-ray beam. It allows the user to easily acquire high resolution XPS spectra from nearly any surface, independent if it is liquid, solid, conductive or nonconductive, without using any additional charge compensation system.

Special System Design

EnviroESCA’s special system design and many NAP-XPS system designs allow for investigations of a large variety of different samples, including insulating samples, gases, liquids and their interfaces that are not accessible with standard XPS systems. The sample to be investigated is the central part of every X-ray Photoelectron (XPS) system.

In a NAP-XPS system or EnviroESCA the sample needs to be positioned underneath the analyzer nozzle which is the entrance to the analysis section of the machine. Samples can be flat surfaces or really rough three dimensions structures. They can be very tiny with a diameter of just few hundreds of microns or as large as 10 mm in NAP-XPS and 120 mm in EnviroESCA.

The effectivity of the Environmental Charge Compensation that is intrinsic to all NAP-XPS systems is shown in the NAP-XPS spectra of zeolites. The NAP-XPS measurements are carried out by using the EnviroESCA system, in 1 mbar air without using an electron source for charge compensation. The sharp peaks in the XPS spectrum are an evidence of the efficient charge compensation process that takes place in gas atmospheres.

NAP-XPS systems as well as EnviroESCA allow for performing XPS measurements on samples kept under gas or liquid vapor environments up to 50 mbar and thus, open up the possibility of investigating fundamental processes in the field of biology, biochemistry, astrobiology, medicine, chemistry, etc. that are not accessible by using conventional XPS systems.