Detail

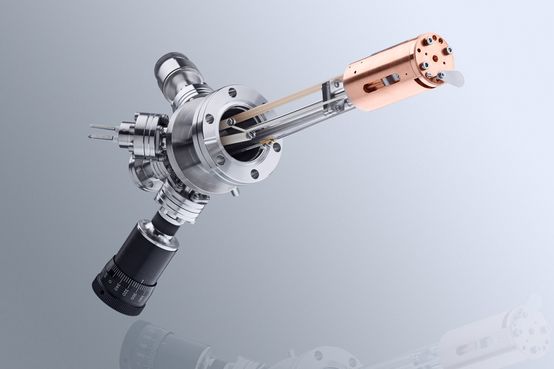

DetailTGC-H

Thermal Gas Cracker Source for the Production of Highly Reactive Hydrogen Atoms

The SPECS TGC-H is a fully UHV compatible thermal gas cracker source using electron bombardment heating of a tungsten capillary to thermally dissociate the gas passing through it. The hydrogen gas molecules are thermally dissociated by high temperature instead of plasma cracking. The cracking efficiency is determined by the equilibrium thermodynamics of the dissociation of hydrogen molecules into atoms. For capillary temperatures of 1400 °C or more and pressures below 10-8 mbar this is nearly 100 %. The small size and thermal mass of the capillary means that very little power is required with negligible heat load into the system. The filament itself is easy to exchange. Moreover, no differential pumping is needed for operation in UHV and due to the electrically grounded capillary zero ion emission is achieved. This small and easy to use source is ideally suited for hydrogen cleaning and surface treatment even for small budgets.

SPECIFICATIONS

| Working Principle | Thermal gas cracker source |

| E-beam power | 0 - 60 W |

| Gas Flow Rate | < 10-5 sccm to 1 sccm (mode dependant) |

| Operating Modes | Atom mode |

| Operating Pressure | < 10-7 - 10-5 mbar |

| Optional Accessories |

| Spot Size | ~34 mm at source |

| Mounting Flange | NW35 CF (2.75 ") |

| Insertion Depth | 200 mm |