Detail

DetailProvenX-DeviSim NAP

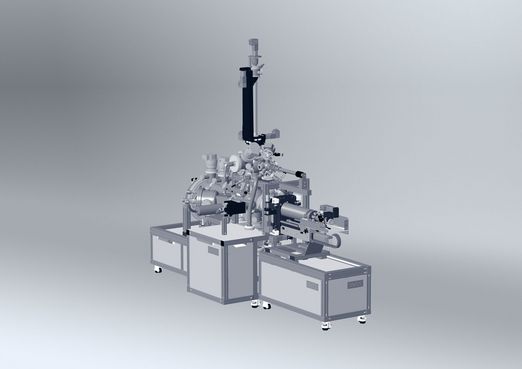

ProvenX DeviSim NAP system for state-of-the-art XPS and UPS analysis under near ambient pressure (NAP) conditions

The ProvenX system series is the quintessence of our long experience in building high performance analysis systems for surface analysis. This system concept combines the most required analysis techniques with the latest and proven technology for ultimate performance.

The SPECS ProvenX DeviSim NAP is a performance optimized system for state of the art measurements from UHV up to more than 30 mbar pressure range for laboratory use. It contains a PHOIBOS 150 NAP analyzer with unsurpassed transmission and angular acceptance, the cutting edge DeviSim NAP in-situ cell as small reactor inserted in the analysis chamber, a high performance small spot monochromatic X-ray source µ-FOCUS 600, a 4-axes manipulator for UHV measurements as well as an optional non-monochromatic UV source UVS 300.

The system comes with a dedicated preparation chamber, an UHV sample storage facility and a multi sample fast entry loadlock. System control is performed by the SpecsLab Prodigy software suite with integrated remote control packages and a computer based vacuum control system.

The system can be equipped with additional sources for material characterization as well as charge neutralization sources. Additonal software and preparation tools are available.

KEY FEATURES

- PHOIBOS 150 NAP energy analyzer with up to +/-22° acceptance angle

- High-performance small spot monochromatic X-ray source with Al Kα anode, spot size < 250 µm

- DeviSim NAP in-situ cell manipulator for NAP measurements up to 30 mbar.

- Different DeviSim in-situ cells are available and intercompatible (DeviSim NAP with e-beam heating, DeviSim NAP-L with laser heating, DeviSim NAP-Peltier with Peltier cooling)

- Analysis module with µ-metal chamber, base pressure < 5 x 10-10 mbar

- optional non-monochromatic source XR 50 for UHV and NAP measurements

- optional non-monochromatic UV source UVS 300 for UHV and NAP-UPS measurements

- FlexMan 4: UHV 4-axes sample manipulator with e-beam heating and LN2 cooling

- SpecsLab Prodigy Software Suite

- Vacuum Control Software for System Operation