Detail

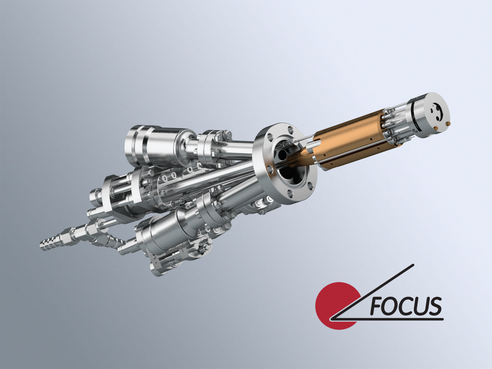

DetailFOCUS EFM 3Ts

Mounted on a DN40 (2 ¾”) flange, the EFM 3T offers the option of sequential or co-deposition of up to 3 materials. The benefits of the classic single source are maintained including linear rod retraction and independent flux monitoring. Adds ion suppression to the EFM 3T to prevent high energetic ions generating defects at the surface.

Based on the design concept of the EFM 3 evaporators, the triple evaporator EFM 3T features three independent cells for the evaporation of a wide range of materials from wires, rods or crucibles.

The three individual cells have crossing beams at about 93 mm distance from the exit aperture (254mm from the mounting flange) to ensure a maximum overlap of the evaporation area.

Each cell is equipped with a separate filament and HV supply to prevent crosstalk. Three independent flux monitors enable the controlled stoichiometric growth of compounds.

The integral multi-position shutter enables precise dosing and simultaneous or consecutive evaporation to produce e.g. super lattices or multilayers.

The latter is easily accomplished by means of the optional shutter motorization and the PC software tool Multi Epitass.

The EFM 3Ts adds an additional electrode to the EFM 3T. To generate a 100 % neutral beam a voltage is applied at the exit of the EFM 3Ts which acts as an ion suppressor.

A part of the evaporant beam in all products of the EFM-series is ionized by the electron bombardment during heating. Most of these ions are captured by the flux monitor electrode. As the evaporant is on high voltage with respect to the grounded sample the remaining ions may create defects in the substrate surface and deposit energy.

The deposition area is governed by the choice of one of three apertures. The three evaporation targets are independently mounted on three 25 mm Z-shifts for alignment. This feature allows evaporation from rods with a multi-pocket instrument. The target materials can be easily refilled from the rear (3x NW 16 CF).

The additional voltage is supplied by the power supply EVC 300s or EVC 100s. In case of co-evaporation each material requires a separate power supply. Only one of these needs to have the s-configuration (EVC 300s, EVC 100s).

KEY FEATURES

- Evaporation area Ø 8.5, 11 and 15 mm

- Working distance 93 mm (± 10 mm)

- 3 independent cells/filaments/ flux monitors

- No crosstalk during compound growth

- Flux monitor

- Integrated multi-position shutter

- Ion suppressor ( neutral evaporant beam )

- Mounting flange NW 35 CF

- All other features same as EFM 3

SPECIFICATIONS

| Number of Pockets | 3 |

| Water Cooling | internal |

| E-beam power | 300 W |

| Operating Pressure | < 10-10 - 10-5 mbar |

| Optional Accessories | Non standard lengths |

| Mounting Flange | NW35CF (2.75 ") |

| Insertion Depth | 210 mm |

| Max. Rod Feed | 25 mm |

| Power Supply | 300 W |

| Shutter | Motorized shutter |